Gold Heap Leaching Process

【Process Introduction】

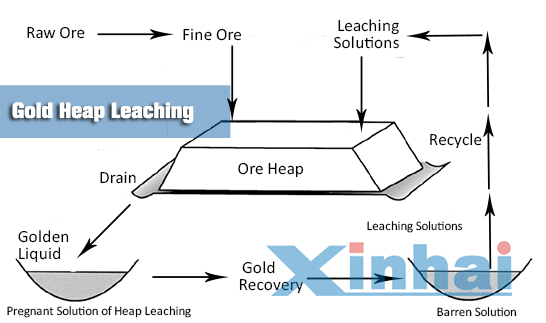

Heap leaching (HL) is a flexible and economic mineral processing method, commonly used to extract gold from low-grade gold ores. In this process, ore is firstly crushed to fine particles. By spraying leaching solution to the large piles, the gold-containing solution is leached. Then used the method of carbon adsorption, zinc powder displacement device and so on to separate gold from the liquid.

【Application】

Heap leaching method is always used for low-grade ore, small gold mine, or both. These ore can not to process by using the conventional method.

[Advantages]

Simple process, less equipment;

Small investment, yield quick returns, and low cost;

The nature, grade, quantity of ore has strong adaptability.

[Process Description]

The raw ore is crushed into fine particles by using jaw crusher or cone crusher produced by Yantai Group;

The crushed fine ore will be heap on the water-proof ground, and set drain aside the ground in advance;

According to different leaching elements, prepare right leaching solutions. For example, gold heap leaching commonly adopt cyanide;

Then the large piles will be sprayed by the leaching solutions, through which the gold-containing solution will be leached from the piles;

Then used the method of carbon adsorption, zinc powder displacement device and so on to separate gold from the liquid. The tail liquid will be recycled.